OE Manifold CRACKED!

#61

I have given some thought to temporarily installing an A/F gauge so I can better quantify the changes to the way the car is running. Jazzista you don't need a Honda tool, you can use a generic Actron reader or a ScanGauge II, either one will reset a CEL. Dee, it isn't the IAT which is reading perfectly normal. I really think its just the ECU having a little fit LOL I'm gonna do the idle learn on Saturday and see what happens. Got and installed my 3Drive throttle controller this afternoon. Man o man do I wish I had gotten one of these a WHILE ago!

#62

I really like my E Drive T/C too.... I googled the code that you had thrown and found the suggestion about cleaning the IAT.... There are a mess of people that are getting the code for a lean condition on GDs with TR 1 intakes.... Some of them had positive results in eliminating the CEL and code by using premium fuel but I know you have a different going on with yours. It would be cool to find out what an A/F meter will come up with....It has been under 80 degrees today, I was out for a drive and saw a IAT reading of 156 while accelerating up a long hill in top gear. driving at about 50 it stayed in the 125 degree area.... I will fix that with a very heavily wrapped Megan street header and some heat barrier insulation on the lower part of the intake and boost tube.

#63

If I were boosted i would look very hard at doing some kind of throttle body coolant bypass. I tried this on mine with just some barbed fittings and some hose clamps and it didn't work. I'm pretty sure it was because i really have no idea what the coolant routing through the TB is. But in my mind the fact that the entrance to the TB has 175 degree water coursing through it can't possibly be helping to keep intake air temps down. I have also thought of extending the line to the IAT sensor and placing it a little further from the TB in my CAI, just to see what happens...

#64

I mentioned the Honda tool to reset ECU, not to clear codes thrown. Bynow no codes are around... yet, at least...

I will reset the ECU by keeping "-" pole detached from Battery for 10 minutes. Then AFAIK it's done when the cooling fan gets on for the second time, with all electrics off... hope this is correct...

#65

would in your opinion apply a coat of VHT flameproof and wrapping be good for my new, still to be installed, WeaponR header? I seem I recall WeaponR disapprove coating the header, but frankly can't understand why. I would try to spray coat both outside and inside, to keep gas hot and header as cool as possible...

Wouldn't such a coating (in and out) be positive for the airbox, intake and the runners too?

Last edited by jazzista; 04-26-2010 at 03:16 AM.

#66

Outside yes, inside not so much. If you were talking about a heat cured finish like Swains I'd say go for it. But anything that comes out of a rattle can will probably break down under stress and end up destroying your catalytic converter. Header wrap is always a good idea for underhood heat management, it just happens to be kinda ugly, in a race-industrial kinda way....

#67

I have read of a guy that wrapped the stainless steel exhaust on his Harley Davidson and had it come apart at the welds and I remember reading that Weapon R said it was a no no to do on their race headers but there is nothing about it on their website now.... I picked up an used header to try it out on and used a mess of wrap over it and an insulation blanket plus numerous coats of a product similar to VHT called D.E.I. I don't know if an exhaust insulation blanket for exhaust headers would void the Weapon R warranty or not. I am not sure about the insulation ability of the high heat coatings but the VHT 2000 degree paint does have silica and ceramic listed as ingredients.... I am using it to prolong the life of the wrap.... I am using A/C and heater duct fiberglass with plastic laminated aluminum foil outer cover on the intake and boost pipes for my supercharger due to their proximity to the exhaust header..... I may try to place some of the same stuff on both sides of a piece of aluminum sheet metal to serve as an additional heat shield between the header the parts mentioned and supercharger..... I think the heater duct insulation would be the best thing to use on the intake parts.

#68

After driving the car for the last week with the throttle controller and the modded intake mani I have some impressions. The additional power is most evident at larger throttle openings, i.e. when you roll into it at mid-RPM. 30-50 times without a downshift are significantly improved, with a downshift, hold on tight! This is with my 3 drive TC set to SP-6, which is my chosen DD setting. I found SP-7 alittle too jumpy in traffic for my tastes. I wish now that i had tried out SP-7 when accelerating to max speed, it may have been even faster! Speaking of which, I had the opportunity to take the car to max speed on I-81 last night (don't flame it was late, and quiet) The amount of extra urge above 4000RPM to redline is startling, whereas before the engine would "hit the wall" at about 100-105MPH she will now pull hard all the way to fuel cut at 6250 RPM. You can run from 80 to 113 in fifth without hesitation, and the car will hold there without complaint. And, sad to say, it feels to me like there is plenty left on the table for more acceleration above the limiter, my calibrated butt says probably 125-130MPH before aerodynamic drag has its way with you. I could not be happier with the way the manifold has worked out, and coupled with the throttle controller I feel like I have resolved the "not enough power" issue once and for all. I may add a b-pipe down the road, but for now I am done....

Last edited by grtpumpkin; 04-29-2010 at 04:28 PM. Reason: thought of somethin else

#70

I do in fact! I have visions of version 2.0 dancing in my head as we speak. Something with PVC pipe glued into the runners to size them down by a 1/2 inch or so. I figure with smaller runners feeding from the larger plenum the funnel effect shoulld in a way "supercharge" the air going into the head. I'm not sure if it will actually work, but I've got this second manifold just sitting around soooooo. I'm incurable, i have a sickness for which there is no cure! LOL

Last edited by grtpumpkin; 04-29-2010 at 09:03 PM.

#71

I am not sure about how that will affect the top end but low to mid range should be very strong..... It is nice that there are folks that appreciate flow velocity verses flow volume... Next you need to pick up a used cylinder head and do a lot of gentle caressing on the ports and a good performance valve job.

#72

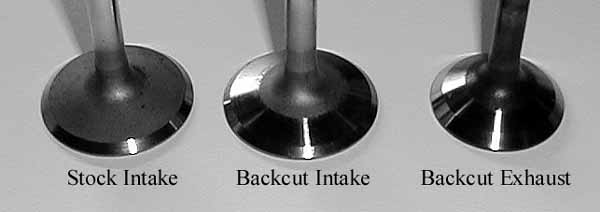

In my research prior to beginning the build-up of the motor for my truck I read quite a bit about back-cutting valves and pocket porting. Both of these do great things for the SB Chevy, but to say the L15 is a different animal would be a slight understatement. I seem to remember Josh (Gd3Kamiwanabe) saying that his machinists had a hard time finding room for improvement in the head of the L15. So maybe get a set of valves and start by back-cutting them and see what happens. Of course Josh is also selling his overbored L series block that has already been clearanced and decked. Nothing builds torque like a bump in displacement! My God what am I saying, my wife would KILL me! LOL After my little experiment on the highway the other night I'm willing to sacrifice a little top end for lower RPM grunt. After all, how many times am I really gonna need to bounce off the speed limiter?

Last edited by grtpumpkin; 04-30-2010 at 11:11 PM.

#73

When you refer to back cutting the valves I am a little lost... I took a motorcycle repair course that was taught by a former teacher of dealer mechanics for Kawasaki who had all kinds of tricks from his early days of setting up factory sponsored racing bikes... He did what he called tulip cutting the back of valves and using valve seat cutters to widen and narrow the seats in the head with three angles.... We did a Honda XR 350 of mine with a 4 valve head, two carburetors and two exhaust pipes but the valves were tiny and we for some reason could only do a 2 angle valve job and it was very competitive in open class cross country competition against 500cc 2 strokes with the only other change being a higher compression forged piston ... Another guy had a XL 600 that we put on a dyno after the same head tricks only put out over 65 HP....The L15A has a longer stroke and smaller bore than the XR 350 so you are right there is very little that can be done due to the tiny size of the valves compared to a SBC but there are twice as many valves per cylinder and only a tiny amount of metal removal per valve port works the same as a larger amount on larger valves.... I would love to get my hands on a used head but it has been over 20 years since I have ported a 4 valve head and 20 years since I did some Harley heads but you could remove spoon fulls of metal from those....... I ordered the High Boost kit from Kraft Works today and now I have to work on our GMC truck so I will have wheels while I have my Fit apart for all of the other things I need to do to it...... I think I am going to do some cutting on the intake manifold.

#74

By back-cutting I mean removing some of the excess material on the top of the valve closest to the stem. Sort of a three angle valve job taken to the extreme. It is supposed to allow for better flow even in short duration cam set-ups. I keep coming back to the idea of having the exhaust side of the head and the lower intake manifold Extrude-Honed. If I ever find a shop within a days drive who will do it for less than an arm and a leg, I may try it....

#75

The extrusion was th rage for use on the pump system on competition jet skis and only could be afforded by racers wit factory sponsorship.... The back cutting of the valves is sounding like what we were doing.... Tapering down allowing a conical shape into the back of the valve to create smoother flow and velocity.... One guy ran a new bike on the dyno and did a trick valve job and another run showed a mind blowing power increase. I think I need to Head Up to Dallas to see my old teacher and see what we could do to fix this thing with some of his tricks...... He hired me to work at the college until I had to move and if I wasn't so far away now I would try to get my old gig back..... He will only drive Hondas but leaves them alone and has been into water crafts.

#76

Thank you,

I stole the idea from here How To: Make your own cold air intake, but yours seems definitely a strong point!

Where can I learn something about the valve job???

Stefano

I stole the idea from here How To: Make your own cold air intake, but yours seems definitely a strong point!

Where can I learn something about the valve job???

Stefano

Outside yes, inside not so much. If you were talking about a heat cured finish like Swains I'd say go for it. But anything that comes out of a rattle can will probably break down under stress and end up destroying your catalytic converter. Header wrap is always a good idea for underhood heat management, it just happens to be kinda ugly, in a race-industrial kinda way....

#78

That is what I did to the valves on my XR350 race bike in 1986. The guy that showed me how referred to it as "tuliping" the valve.... That and narrow valve seats toward the outside of the seats will do as much for an engine as changing to a mild performance camshaft.

#79

I have heard it referred to as "tulip cutting" as well. Thanks for the pic Marko, that is exactly what I was trying to demonstrate. I only wonder how far we can go with the OE ECU before a stand-alone would make more sense. It seems that Honda intended the L15 to serve economy duty and the programming in the ECU probably reflects this.

#80

You can pick up a used ECU for something over $400.00 and have it reflashed in I believe Taiwan.... LEK post here and has had it done to his car.....The stand alone doesn't seem to always work I have been told... Search LEK and see what he can do for you , he does JDM parts for USDM parts and I think he can hook you up for a reflash.... if you need an AEM IF/C I may be able to get you fixed up with 1 if that route will work for you..... A hondata reflash is only available with the package I just ordered.... There has to be some good photos of a head that has been disassembled somewhere to check out to see if it is viable to get the results from the valves and seats.